ISO 45001 OHS Management System

September 21, 2024

16 min read

37ISO 45001: The first international OH&S Standard

ISO has published the 45001 standard to help organisations improve their health and safety performance by creating safer work conditions, where injuries and diseases are prevented, and lives are saved.

Up to 90 experts worked together for five years, and their work resulted in the first international occupational health and safety standard that specifies requirements for an occupational health and safety management system (OHSMS), to enable an organisation to proactively improve its OH&S performance by preventing injury and ill-health.

ISO 45001 is a fresh answer to the old world scale concern about health and safety at work. It wants to put health and safety at the core of the business strategy and change the way both employees and employers think of their well-being at work.

This standard shares many basic ideas about safety but separates itself from the others by taking a new perspective towards the biggest occupational safety challenges that make it difficult for a company to protect its people.

Why does OH&S matter?

People keep organisations alive with their work, commitment, and motivation. The existence of any business depends on its employees; this is a fact that will never change. Therefore, it is fair to say that the first responsibility of any organisation towards its people is to keep them safe and send them home to their families in full health. However, statistics tell another story.

Data shows that each year over 2.78 million people lose their lives just because they’re doing their job; this number is more than half of the population of Sydney. Many more people are suffering from work-related diseases and injuries that can change their lives forever. This is why health and safety at work have been among the common concerns of businesses around the globe for many years now.

Organisations need guidelines to show them the best way of protecting their workers. This demand for safety guidelines has led to various occupational health and safety standards.

However, there was still room for another standard to improve occupational safety and consider new changes in the business environment. A new standard that goes beyond basics and integrates into the overall business process of companies.

ISO stepped in to fill the gap and provide organisations with a new exciting opportunity to make their environments a safer and better place for work.

Safety challenges solved by ISO 45001

Members of the ISO Health and Safety Committee wanted to create a standard that could make a real difference in health and safety at work. To do so, the standard had to be capable of dealing with a range of safety challenges. By going through the standard requirements, we can say that ISO 45001 has been able to target the most critical safety challenges and provide organisations with different tools to overcome them.

Prevention of safety issues

ISO 45001 puts a strong emphasis on identifying and controlling hazards and risks to avoid accidents or threats to health and safety. The standard makes a comprehensive effort to address all the activities or elements that could harm people in order to prevent safety issues in the first place.

ISO realises that among the different management systems in an organisation, the health and safety system is the one that needs the greatest amount of proactivity; otherwise, the results could be catastrophic. The Plan, Do, Check, Act (PDCA) model makes sure that organisations are continually improving and the process of identifying risk and hazards never stops.

Developing a health and safety culture

Unfortunately, if an organisation has not previously had a formal OHSMS in place, there may not be a prioritisation of health and safety practices in everyday work activities. Workers may not consider health and safety a priority if they have not personally been involved in a safety incident, or witnessed others in one.

Developing a health and safety culture promotes OHSMS practices and creates awareness of hazards and risks. Sections 7.2 (competence) and 7.3 (awareness) of ISO 45001 help to address this. Workers should be adequately trained and be made aware of the organisation’s OH&S policy and objectives.

ISO 45001 requires organisations to consult with their workers. This includes asking for their opinions and engaging with them on matters relating to OH&S. This contributes to the health and safety culture and makes workers feel involved in the OHSMS, as well as understand how their actions contribute to the overall success of the OHSMS.

The intent of ISO 45001 is to make safety everyone’s responsibility and to create an environment where workers can express their safety concerns with management and know that their concerns are recognised and respected.

Commitment from Top Management

Commitment from Top Management is critical to the overall success of the OHSMS. As per Section 5.1 of ISO 45001 some of the ways that Top Management can demonstrate their commitment include:

- Ensuring the OH&S policy is compatible with businesses processes and the strategic direction of the organisation.

- Ensuring that the resources required to establish, implement, maintain and improve the OHSMS are available.

- Communicating the importance of effective OH&S management and conforming to the OHSMS requirements.

- Developing, leading and promoting a culture in the organisation that supports the intended outcomes of the OHSMS.

- Ensuring that the organisation establishes and implements a process for consultation.

5 major benefits of ISO 45001

Below we have outlined 5 of the key benefits that your organisation can expect to receive:

Safety reputation and competitive advantage

ISO 45001 is an internationally recognised standard. Achieving ISO 45001 certification demonstrates that your organisation is committed to the welfare of your employees and external parties. This can help to position your organisation as a trusted partner and differentiate yourself from competitors who are not ISO 45001 certified.

Cost saving

ISO 45001 minimises the risk of downtime through accidents and provides possible cost saving through public liability insurance premiums. Identifying hazards and controlling risks at the earliest stage could help reducing business cost by preventing safety issues.

Employee motivation

Leadership commitment to a health and safety culture can change the way employees think about how their actions contribute to keeping themselves and everyone else safe. Seeing Management leading by example means employees are more likely to be motivated to adopt health and safety practices which in turns leads to being more productive.

Continual improvement

Certification to ISO 45001 demonstrates a strong commitment to the ongoing improvement of safety performance. Continual improvement is essential to the ongoing success of the OHSMS.

Third-party feedback

Having an external third party audit the performance of your OHSMS is essential for picking up and remediating any gaps within the OHSMS and to ensuring ongoing continual improvement.

Integrating 45001 into other management systems

If your organisation is already certified another ISO standard such as 9001 or 14001 you’ll notice the same look and feel as ISO 45001. The reason is the matching core text and common terms and definitions that all of these standards share which comes from adopting the new high-level structure of Annex SL.

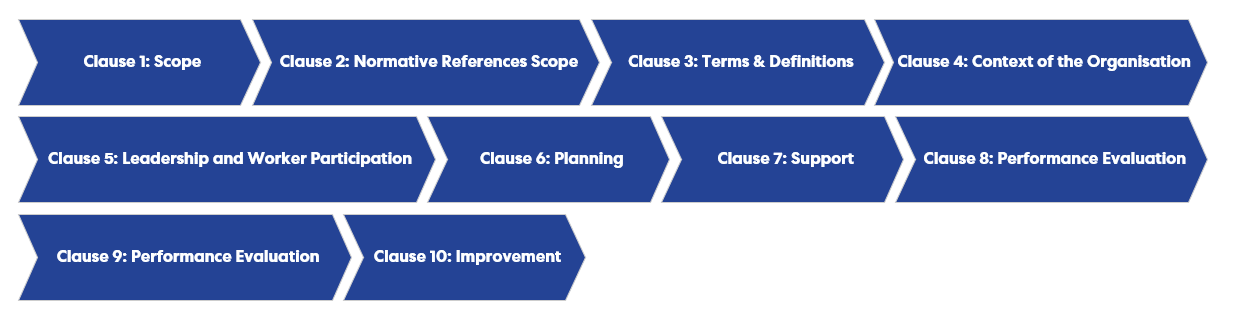

This high-level framework includes 10 clauses as below:

All of the new ISO standards are developed using these 10 clauses. This identical structure aims to help organisations to easily integrate more than one ISO standard and avoid conflict, confusion and extra effort.

However, the real capacity of this framework is in not fully understood unless it’s combined with the Plan- Do-Check-Act cycle (PDCA). PDCA is a powerful tool that if used in the correct way it can move the needle in the organisations’ performance.

The combination of Annex SL framework and PDCA model helps organisations to see their management systems as a never-ending loop that only improves and becomes a better version of what it was before. In fact, the 10 clauses of standard don’t have a linear relationship together, on the contrary, they are different parts of a process to achieve the management system goals.

The whole process is the same for all of the ISO standards so organisations can benefit from the simplicity of integrating different standards together.

Requirements

Below is an outline of Clause 1-10 of ISO 45001:

Clause 1: Scope

This clause refers to the intent of ISO 45001, which is continual improvement of safety in organisations fulfilling legal requirements.

Clause 2: Normative references

This standard has no normative reference.

Clause 3: Terms and Definitions

This clause provides the list of terms and definitions in ISO 45001.

Clause 4: Context of the Organisation

Context of organisation simply refers to all of the internal and external issues that can affect your OHSMS’ ability to reach its intended objectives. In this step, you must identify all those issues that are specific to your own organisation.

Another term in this clause is interested parties, which means organisations have to consider the needs and expectations of all the internal and external parties that can have an impact on their OHSMS, not just their employees. These internal and external parties could be stakeholders, unions, governments, etc.

The important point here is to know your company’s environment inside and out, so that you can create scope for your OHSMS.

Clause 5: Leadership and Participation

The importance of Top Management engagement in the OHSMS is outlined in this Clause. These are the tasks that leadership must be accountable for:

- Effectiveness of OHSMS and its integration to the overall business process

- Alignment of OHSMS policy with the organisation’s strategic direction and objectives

- Allocating the adequate resources to OHSMS

- Assigning responsibilities and authorities to the right people

- Supporting the safety culture and open communications among all levels of the organisation

Clause 6: Planning

This Clause talks about creating plans to achieve intended outcomes of the OHSMS and considerations for risks and opportunities along the way. Some of its key points include:

- In case of hazard identification and control, ISO 45001 takes a proactive rather than reactive approach, and it considers a wider range of people who could be affected by the organisation’s operation, not just people who are in the building. These people could be contractors, temporary workers, visitors and even other companies functioning in the same location. Besides, a business must determine changes that affect OHSMS.

- Organisations need to have a process in place to identify risks and opportunities

- The action plan must consider risks, opportunities and legal requirements as well as steps to address them.

- Goals of the OHSMS must be consistent with the health and safety policy and legal requirements. These goals also need to be measurable, communicated among all, and regularly updated.

- Actions to achieve the goals must have adequate resources.

Clause 7: Support

Support refers to the competency and awareness needed for meeting health and safety objectives, documenting information and the overall effectiveness of the OHSMS. This includes:

- Determining and documenting required competencies for staff who can affect the performance of the OHSMS.

- Evaluating the effectiveness of these competencies to ensure that everyone is capable of performing their role.

- Ensuring that workers are aware of all of the information they need to know about ISO 45001 requirements.

- Determining communication requirements for both internal and external parties.

Clause 8: Operation

The required actions to implement the plans of clause 6 are included in this Clause. Organisations need to consider the following aspects:

- Identifying hazards and evaluating the risks.

- Addressing temporary or permanent changes in the organisation that can affect OHSMS outcomes.

- Ensuring that the procurement of products and services are aligned with the OHSMS requirements.

- Predicting and preparing proper actions for the emergency situations.

Clause 9: Performance Evaluation

This Clause talks about the process of evaluating the performance of OHSMS.

Here is what organisations need to do:

- Determine how the OHSMS performance will be evaluated including who, where, how often etc.

- There must be an internal audit report that contains the results to all interested parties that might be affected by that information.

- Another method of monitoring the OHSMS performance is management review meetings. The standard gives clear instruction about how these meetings should be conducted and what should be expected in terms of input and output. Top Management should be responsible for the management review meeting.

Clause 10: Improvement

This Clause directly outlines the importance of proactively looking for and acting on improvement opportunities. To be able to do that organisations should:

- Look for the improvement before a nonconformity occurs and take any necessary action before an accident/ incident occurs.

- Conduct timely investigations of any nonconformities that arise and then take the necessary actions to correct the nonconformity or to remove the root cause if possible.

- Evaluate any implemented actions to ensure their effectiveness.

- Communicate the results of the evaluation to all related parties.

- Create a health and safety culture which includes effective communications and maintaining records of actions and improvements.

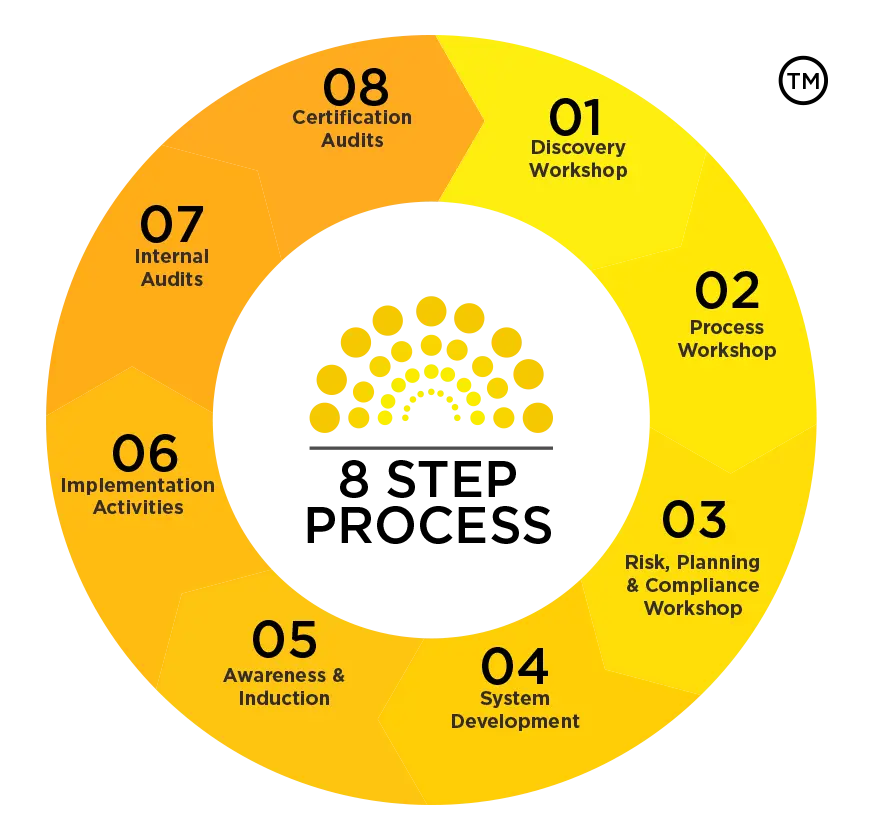

8 Steps to ISO certification

Here at Compliance Council, we specialise in assisting organisations with developing and implementing management systems, which put your business on the path to becoming certified.

Our 8 Step Process is designed to give your organisation the most efficient turnaround time whilst delivering service that is second to none. Please see the 8 steps below:

What does an ISO certification body do: Stage 1 and Stage 2 with audit certification body

Third Party Certification is the process of having your Management System audited by an independent third party. This type of auditing is typically used by Conformity Assessment Bodies (CABs) who are regulated by a government organisation known as JAS-ANZ. These CABs can issue registered certificates of compliance to various standards such as ISO 9001, ISO 45001, and ISO 14001.

Stage 1 and Stage 2

The formal assessment process includes two stages. In Stage 1, the auditing body will confirm whether you have met the requirements of your proposed scope and the objectives you have set for yourself. If there is any kind of minor or major nonconformities, the auditing body will give you some time to address these, before beginning the Stage 2 audit. In Stage 2, your system will be assessed again to make sure that all nonconformities are corrected.

At this point, if there are no remaining nonconformities, your certification can be issued; otherwise, you will be given time to correct existing nonconformities before the next visit of the audit and only after removing all the major nonconformities you will be eligible for ISO 45001 certification.

Surveillance Audit

Typically, the certification body will do yearly surveillance of your management system for the first three years after your certification is issued. This way, you can ensure that your OHSMS continues to meet the requirements of ISO 45001 after certification has been achieved.

Frequently Asked Questions

As a leading provider of consultancy services we cover a wide range of disciplines including quality compliance, safety compliance and environmental compliance across high-risk industries.

ISO 45001/Occupational Health and Safety Management Systems are applicable to all industries and areas; the key ones we work with include high risk industries such as construction, manufacturing, aviation, professional services, healthcare, and transport.

An Occupational Health and Safety (OHS) Management System alone won’t add any value to your business or your staff. If the OHS Management System is designed to fit into the existing operations of the business, and with input from the expected staff who will be using the system, then you will start seeing improvement.

You can expect the following improvements from implementing an OHS Management System:

- Reduction of safety issues

- Cost savings through the minimised risk of downtime caused by accidents/ injuries.

- If certified, recognition from your customers for achieving certification and increased confidence from prospective customers

These are some of the benefits of an OHS Management System although there are many more that an organisation can achieve if it adopts the system into its core operations.

Third Party Certification is the process of having your Management System audited by an independent third party. This type of auditing is typically used by Conformity Assessment Bodies (CABs) who are regulated by a government organisation known as JAS-ANZ. These CABs can issue registered certificates of compliance to various standards such as ISO 9001, ISO 45001 and ISO 14001.

Unlike many competitors who operate by a time and materials model, we operate by a fixed-fee model. We provide clients with proposals that outline the methodology for the project, the deliverables, and the total cost.

Separately on your end, you'll need to engage the external third-party certification company whose cost will be in addition to our cost. We can definitely put you in touch with certification companies.

Yes, the initial consultation meeting with you to gauge what certification would be suitable for the business and also get an understanding of how the business works is free so that we can provide an accurate proposal.

4-6 months (client preparedness plays a major role here).

If there is a tender or client demand for urgency, we and the Certification company can write you a Letter of Commencement, upon request.

Why Compliance Council?

Compliance Council are compliance consulting experts for high-risk industries across Australia. As a leading provider of consultancy services, we cover a wide range of disciplines. These include safety, quality and environmental compliance across all high-risk industries. Our team of professionals have significant experience gained by working with companies of all sizes, ranging from startups to multinational corporations. The need for compliance in Australia is becoming increasingly prevalent, especially given the high standards and demands placed on businesses and providers of goods and services. Compliance Council strive to take the burden and stress of meeting these industry standards, in what can often be a time-heavy obligation for time poor industries.

Contact us today to discuss how our experienced consultants can assist your organisation with achieving ISO 45001 certification.

Conatct UsSign up for our newsletter

Stay Ahead: Subscribe for the Latest Compliance Insights and Updates.

We care about the protection of your data. Read ourPrivacy Policy.